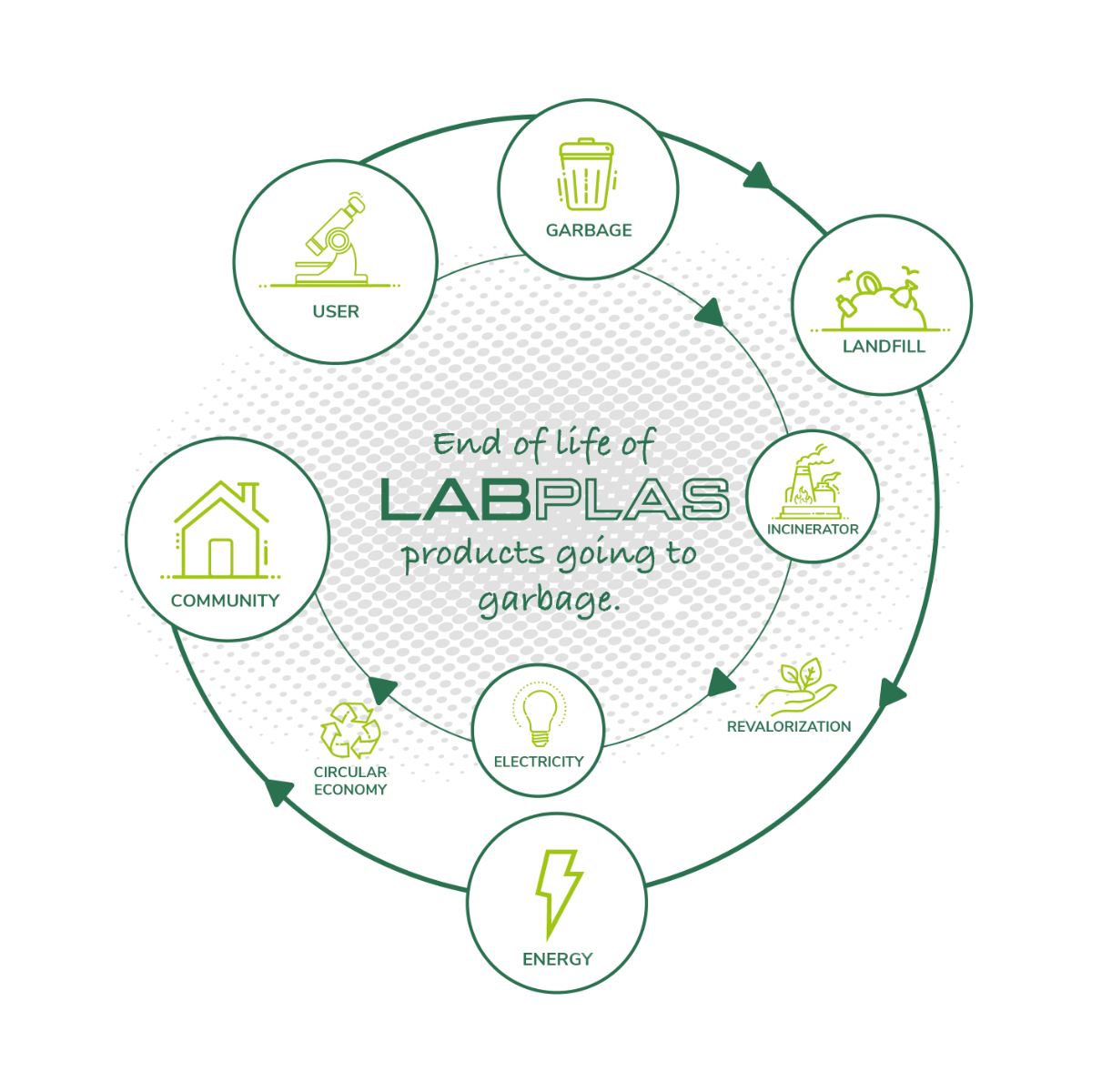

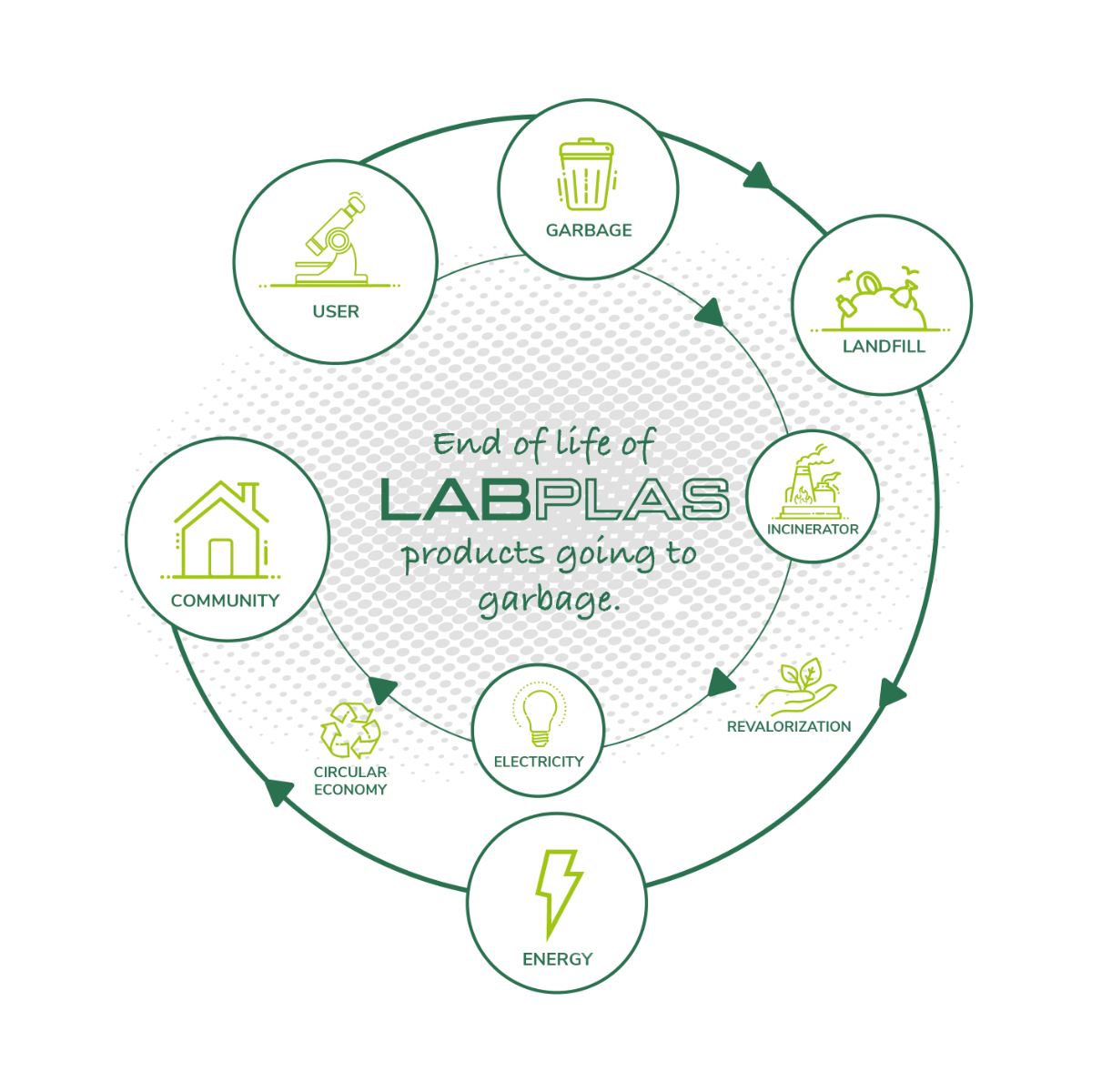

What End of Life means

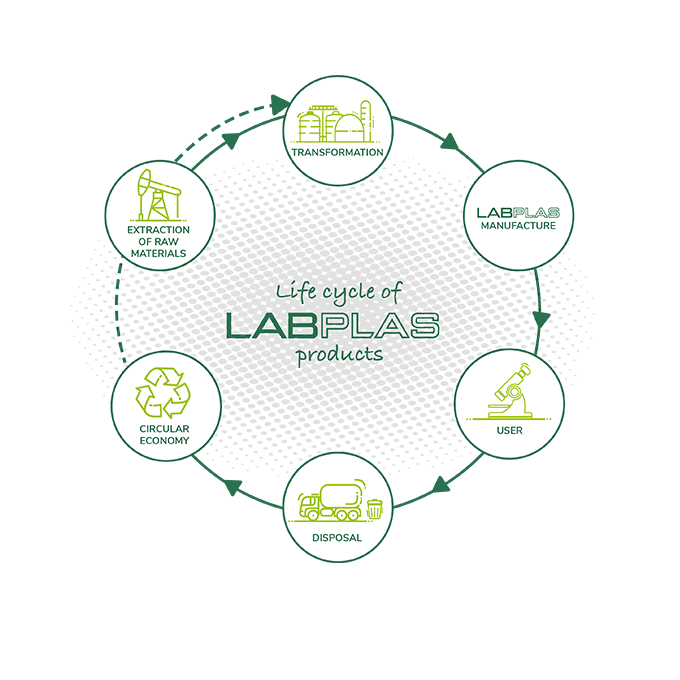

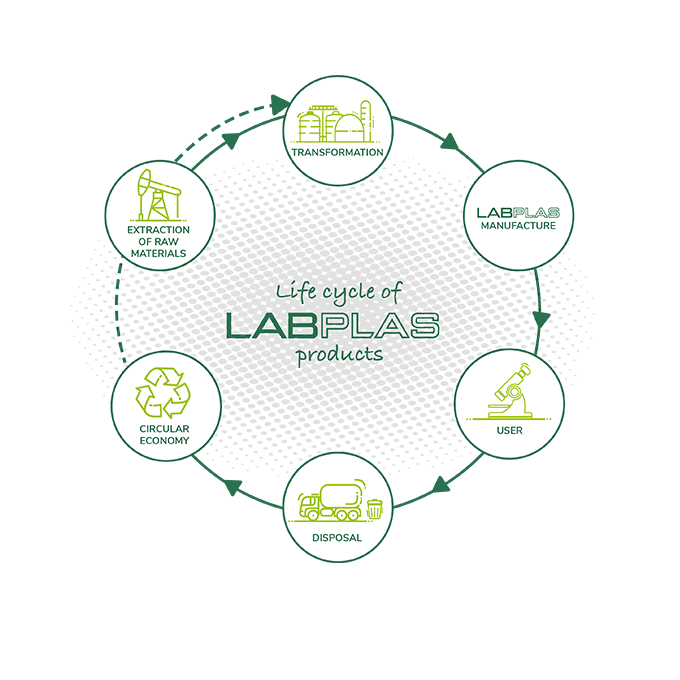

Consumption trends are constantly changing, and we are aware that all goods have a fixed lifespan. Whether it is food, a car, or a sterile sampling bag, once used for the last time, the user must dispose of that product. Depending on the nature of the product, it can have different end destinations. It may be composted, recycled, or disposed of in the garbage. By considering these end-of-life options when purchasing products, a user has the potential to contribute to more sustainable and environmentally friendly consumption.

Why it is important to us

At LABPLAS, being environmentally responsible has always been at the heart of our priorities and has always been an integral part of our business strategies. This is one of the reasons we created our first biodegradable product in 2008. We are proud to be the only company on the market to offer a full range of biodegradable sterile sampling products. It is in this spirit of innovation and continuous improvement that we continue our research and development activities day after day to provide our customers with more innovative and ethical products, without sacrificing quality. Once your operations are completed as usual, we encourage you to send our products to their relevant end-of-life areas to help ensure a more sustainable consumption cycle. Doing so will reduce their impact on the environment, while also contributing to the circular economy!

Products going to waste

Waste and incinerator

Using our LABPLAS products is simple and convenient. The design of our product lines makes it easy to discard after use. You don’t have to worry about how they are disposed of, as they can be disposed of in the garbage or incinerated safely. In addition to following the safety guidelines specific to the nature of your job, simply discard our bags once you have finished using them. We know that safety and ease of use are important for our customers, which is why we made sure our products meet those requirements.

Biodegradable line

The products in the biodegradable line decompose much faster than ordinary plastic, without compromising the quality of the product. This is possible thanks to their composition. Our recipe accelerates the rate of degradation by attracting microorganisms that promote enzymatic degradation (or depolymerization) of plastic into smaller molecules.

Contribution to the circular economy:

Even after disposal, LABPLAS biodegradable products continue to make a positive contribution to the community! Rather than becoming completely inert waste, these products will degrade and release CO2 and CH4. At landfill sites equipped with gas collection and control systems, they will be collected and reused as natural gas to meet people's heating and energy needs. All this thanks to the unique composition of LABPLAS biodegradable products.

All LABPLAS products are compatible with incineration. They do not cause stress or damage to the incinerator. They also burn like all polymer families to which they belong respectively. By burning our products, incineration plants also contribute to the community. This is due to a process in which the heat produced during incineration is used to heat a water container. When water boils, it rotates turbines, which in turn produce electricity. This energy is then reoriented towards the population to complete the circular economy loop!

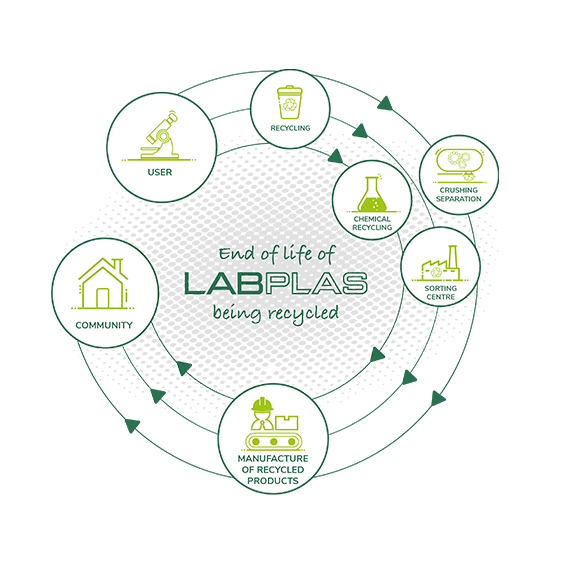

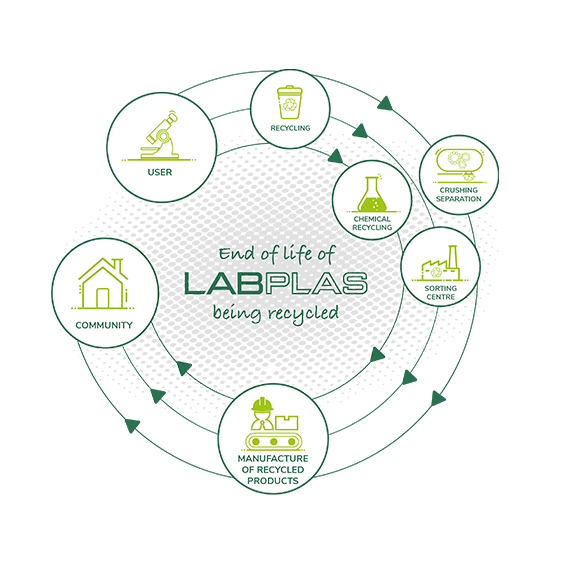

Recyclable Products

Information on these products

The majority of LABPLAS products are made from recyclable plastics. Because of the high quality standard expected of our bags, our products must be made of virgin polyethylene (LDPE). This level of purity makes them highly recyclable. This means that the polyethylene elements in our bags are mostly or nearly fully recyclable and significantly increase their post consumption value.

LAPLAS products made from laminates (that is, those with multiple layers) are also recyclable. It is important to note that this can only be achieved through appropriate recycling services, such as:

- Chemical recycling: Chemical recycling involves dissolving and extracting one layer of plastic from our bags. Plastics have different levels of solvent solubility. Using a specific solvent, only one of the plastics dissolves, thereby isolating them from one another. This is how plastics can be separated and processed to create recycled plastic products.

- Recycling by crushing with separation process: Crushing is the action of mechanically breaking the bags and then separating the layers in the water through their different levels of flotation. Once separated, plastics can be reintroduced into the circular economy.

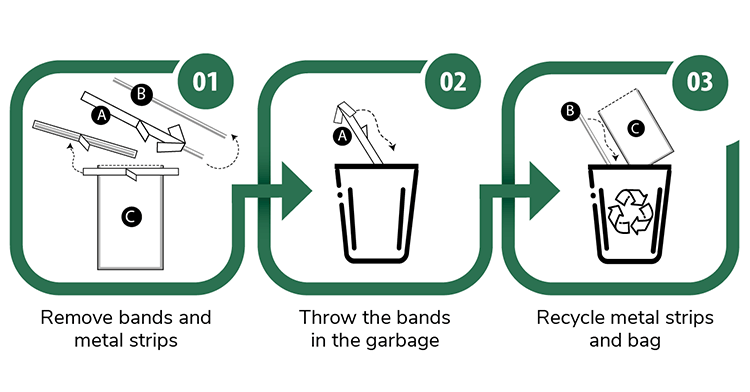

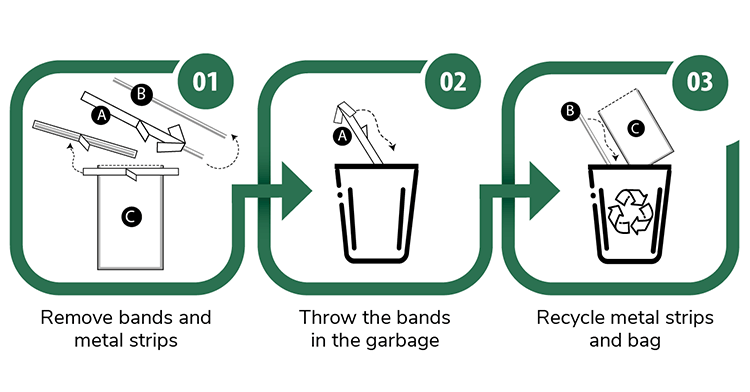

How to Dispose of LABPLAS Recyclable Products

After completing your operations as usual, follow these steps to safely dispose of our recyclable bags:

* Always follow the safety instructions that apply to the nature of your work

Why follow these steps?

As mentioned above, LABPLAS bags are made of high-quality plastics to meet the highest standards of use, which facilitates their recycling. By participating in recycling, you can help reduce the impacts on the natural environments in which the extraction of raw materials is typically carried out, thus contributing to a virtuous wheel.